After that first successful

flight off the grass strip west in Middleburg,

Va. the plan was to finalize the AIRPHIBIANS

design, get FAA certification and start limited

production. The Danbury, Conn airport was the

chosen site. Bob had made overtures, found a

piece of land, 15 acres, on the airport and had proposed to

the town officials that the newly

formed CONTINENTAL INC be allowed to buy the land

and build a factory for production of an

exciting secret project. The Danbury officials

were skeptical but enough members who questioned

the validity of the present one business HATTOWN, believed "here was another industry" even

though it was secret. This was an example of the

charm of Bob Fulton.

So the team became real and everyone moved to

the Danbury area. I was married, and at that

time had 3 children, Frazer P, Rush H and

Ariel M. We rented a house in Newtown and then

finally bought a small red mill house on a small

stream in the Plumtrees district of Bethel,

about 15 minutes from the Danbury airport.

The initial 'team' was Bob, Ted, Dash and me.

Our first tasks were to get the building useable

and I clearly remember digging the well. Again

we were all there, it was a freezing cold day,

someone had to go down in the well and dig. I

was chosen and by then it was about 15 ft deep,

I went down to the bottom, it was cozy and warm and those three were

up there looking down and freezing while I dug.

I don't remember the date that the AIRPHIBIAN arrived,

but soon we had the shop cleaned up, filled with equipment and began

the process of limited production.

We needed more help. There was a local tool and die maker

by the name of Fred Underhill who lived across the road. Fred was a lovely man and all of the

complicated machine modifications were done

entirely by him. He bored out the back end of the

aircraft engine crankshaft and built a

tapered arbor to be heat shrunk onto the

crankshaft on which to hang 'something' that

would be part of the auto drive system. First we

hung a large generator on that arbor, then a

large multi belt pulley. No easy task!

An engineer was needed, so Bob found Ross

Stevens who made various designs and drawings.

They were used by Fred and

Dash to make parts and assemblies and out came the AIRPHIBIAN. My first real

task was to take the auto/plane machine that I

first flew and review every part to make it lighter.

A lot of the original was cold rolled steel, I

substituted 24ST aluminum which is equally strong

and much lighter. I do not remember how much I saved

but I went over each part to lighten the weight.

When I flew the AIRPHIBIAN that first day

there was no 'drive system' yet installed. The

plane auto disconnect system was however in

place and

except for refinements is almost the same as it

is today.

The propeller quick take off was developed and

refined during those early times in Danbury.

Over time I became more familiar with

the flying characteristics.

So at this point there was Bob Fulton, President; Franz

Alverez, VP and Engineer; Ted Polhemus

Mechanical and Electrical Master; Wayne Dasher

(Dash), top flight A&E Mechanic; Fred, Tool and

Die Maker; Ross

Stevens, Aeronautical Engineer and Structural

Engineer and myself as Test

Pilot.

Frazer Dougherty - October

2006 |

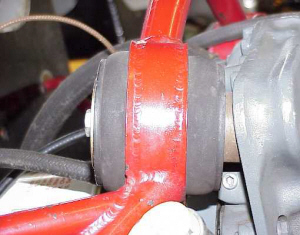

Plane Controls

goodyear lord mount |

|

|